Production Process Tracking In The QR Mobile Data Software

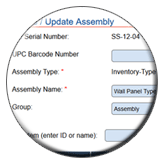

In the QR Mobile Data software you can define everything that you want to track, record and report via the intuitive web interface. Shop floor employees

track materials usage and manufacturing work orders on the shop floor using mobile devices and QR code / barcode / NFC or BLE tags scanning.

Real time reports are available to all authorized users of the software.

- Custom production process workflow. Define your manufacturing process and process steps via the web dashboard.

- Custom mobile forms for data collection. Use digital forms builder

tool in the QR Mobile Data software to create

mobile forms for the production process documentation. QR Mobile Data software capabilities allow you to create mobile forms that are informative,

customizable and are easy to complete.

Details on the digital forms capabilities in the QR Mobile Data software are available here.

- Link mobile forms to the workflow. Attach mobile forms to the production process steps. Company employees will see which forms need to be completed on the current step,

and will be able to fill out relevant forms on the smartphones or tablets.

- Barcode / QR code scanning.

QR code scanning allows shop floor employees to quickly identify a work order or component, access relevant information and documentation,

move a work order to the next step and complete required forms - all on the shop floor using mobile devices. All relevant information can be scanned in

instead of being entered into the form manually.

- Backend cloud software. All data collected on the shop floor on the smartphones or tablets is sent to

the backend cloud software in real time.

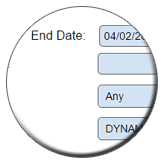

- Real time production status reports. Authorized QR Mobile Data software users can access live status of everything in production,

as well as production process history for the past work orders on demand from anywhere.

- IoT based production process tracking. Use BLE tags and IoT gateways to automatically track

manufacturing work orders through the production process tracking without any human participation.

- IoT sensors for the climate conditions monitoring. If you are dealing with the temperature or

humidity sensitive components or materials, an IoT module will allow you to automatically monitor temperature and humidity conditions of

materials and components as they are stored and are moved through the production process.

More on IoT conditions monitoring