Traceability and quality control for the manufacturing process require employees to record lot numbers of all used materials,

details of each production step and fill out quality control forms. QR Mobile Data makes this process simple, fast and error-proof.

Your employees can record everything on site, in real time using mobile devices (smartphones or tablets) for barcode scanning,

filling out mobile quality control forms and information look up. All documentation is stored in a secure cloud and is accessible on demand

in real time by authorized personnel.

Create Custom Mobile Forms For Quality Control And Data Collection

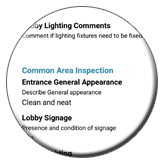

- Create custom quality control forms and checklists via the web interface.

- Create as many different quality control forms as you need, and attach each form to the relevant workflow step(s) or procedure(s).

- Employees on the shop floor use mobile devices (smartphones or tablets running iOS or android) to scan a product, access it's current

production status and see which quality control form(s) need to be filled out on the current step.

- Completed forms are sent to the centralized cloud database and are available for the immediate access / review by everyone involved in the project.

- Depending on the inspection results, an employee can move the product to the next step, correct the problem and record what had been done, or discard the product. All employee's actions are

recorded and become a part of the production history.

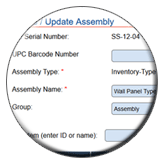

Traceability: Track Lot Numbers Of The Components On The Shop Floor

- Track materials and finished products by lot number, serial number or SKU.

- Enter information on each materials lot on site using mobile devices. Define what information do you want to keep via the web dashboard.

- Record building of the final product and lot number of components on the shop floor using mobile devices for barcode / QR code scanning and data entry.

- Collect additional data required for traceability, such as instruments and containers used in the production, pressure and temperature conditions, etc. using mobile forms.

- Record where the final product is shipped, and any additional parameters (such as tracking numbers, etc.)

- Review lot numbers of components, collected data and production steps for all finished products.

- Review where each batch of the finished product was distributed or stored in case of recall

- Find all batches of the final product that contains a specific ingredient lot number.

-

Create Custom PDF Documents For Internal And External Audits

- Create an MS Word template for each quality control form / checklist to define PDF document look and layout.

- Include your branding (logo, address, etc.) in pdf document.

- Include information on the assembly or product batch that was inspected. Assembly or product batch information will be inserted dynamically

when pdf is created.

- Include results of the quality control.

- Email created pdf documents to internal or external auditors, from the mobile devices or admin web dashboard.